RSVD R8 - Rolling Stock Vision Diagnosis

RSVD R8 is a device capable of moving underneath the rolling stock subjected to technical verification, without the need to position it in specially equipped areas (the rolling stock shall simply be placed on the tracks, in any area). The device allows to carry out measurements and acquire images of the critical components and parts positioned under the body and on the sides: RSVD system allows to carry out, on the basis of these images, accurate and highly reliable measurements for the checks of correct assembly, levels of wear and integrity which constitute The essential data for the Periodical Verifications. The images acquired by RSVD and the measurements made are automatically recorded and made available (remotely) to the managers in charge of making the appropriate assessments. RSVD allows a considerable reduction of time and costs necessary for carrying out the checks, eliminating the need for equipped areas, carrying out complex surveys and measurements automatically and with high precision and reliability in conditions that are often not easy for a human operator, allowing the automatic registration of the surveys carried out.

Technical Characteristics:

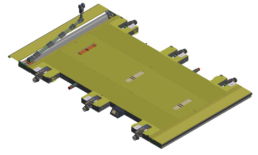

Info Mechanics:

- Chassis: Aluminium alloy

- Overall dimensions; 2140 x 1340 x 65 mm

- Weight: 90 Kg

- Environment working temperature: 0 ÷ 40°C

- Power Supply: Battery

- Supply Charge: 220Vac 50hz

- Envirinment Protection Degree: IP56

- Shocks Protection Degree: IK8

- Max Speed: 30 mt / min

- Analyzing speed: 1,2 mt / min

Info Camera:

- Onboard Cameras: n.2

- Image definition: Full HD 1080p

- Camera support max extension (X- Z axis): 650mm

Info User Interface:

- Remote by PC / Tablet

- Comunicazione Remoto / RSVD : Radio

RSVD R8 - Rolling Stock Vision Diagnosis

Advantages

- RSVD device is designed to move with its own motorization on the tracks, covering the entire length under-car of the rolling stock subject to verification.

- RSVD technology allows to carry out, on the basis of collected images, accurate and highly reliable measurements for the checks of correct assembly, levels of wear and integrity that constitute the essential data for the Verifications

- Images acquired by RSVD and the measurements made are automatically recorded and made available (remotely) to the technicians in charge of making the appropriate assessments.

- RSVD system introduces the possibility of performing these checks remotely, using the most modern technologies of video-imaging and image processing software for carrying out the surveys and measurements necessary for the technical checks, as well as directly carrying out measurements and surveys with specific instrumentation, and making the data available remotely in real time.

- The introduction of these technological systems allows, in addition to a simplification of the activities (often these checks must be carried out in dedicated areas and equipped with inspection pits under the car) and consequent reduction in costs, also an increase in the precision and reliability of the measurements carried out (the logistical conditions in which these checks are carried out are often difficult for operators, with possible detriment of the correctness and reliability of the measurements and surveys), and therefore a consequent increase in the safety level of the railway system.